Tech Update: Volcanic Repreve

Firewire introduces the Seaside & Beyond and Sunday models in Volcanic Repreve technology.

Both models will be offered exclusively in this technology going forward.

As the world’s leading brand of recycled fiber made from ocean-bound plastic bottles, Repreve® is a sustainable innovation enabling Firewire to build strength and flex control into each Volcanic shape while simultaneously preventing plastic bottles from entering our ocean playground.

Key Benefits

- Enhanced Strength and Flexibility: Repreve fibers provide exceptional strength and flexibility, making Firewire's basalt cloth lamination comparable to traditional carbon fiber in terms of performance. The integration of these fibers ensures that each board can withstand rigorous conditions while maintaining optimal flex control.

- Sustainable Innovation: By using Repreve fibers, we help divert plastic bottles from oceans and landfills. This sustainable approach reduces carbon emissions and conserves energy compared to using virgin polyester. Firewire's commitment to the environment is reflected in every board they produce.

- Superior Resistance: The basalt fibers in Firewire's lamination process offer excellent resistance to alkaline, acidic, and saltwater conditions, ensuring longevity and durability in diverse environments. This makes Firewire boards not only high-performing but also reliable over time.

- Cooling Properties: Firewire's lamination process includes vacuum bagging with white polymer pigments. This feature helps keep the boards cooler in direct sunlight compared to traditional black carbon laminations, providing long lifespan of the product.

- Eco-Friendly Surfboards: "Each surfboard is crafted with Repreve fibers, transforming recycled plastic bottles into high-performance, sustainable products."

- Performance Meets Sustainability: "Experience the perfect blend of strength, flexibility, and environmental responsibility with our basalt cloth lamination reinforced by Repreve fibers."

- Stay Cool Under Pressure: "Vacuum bagged with white polymer pigments, our boards stay cooler and deliver top-notch performance, even in the harshest conditions."

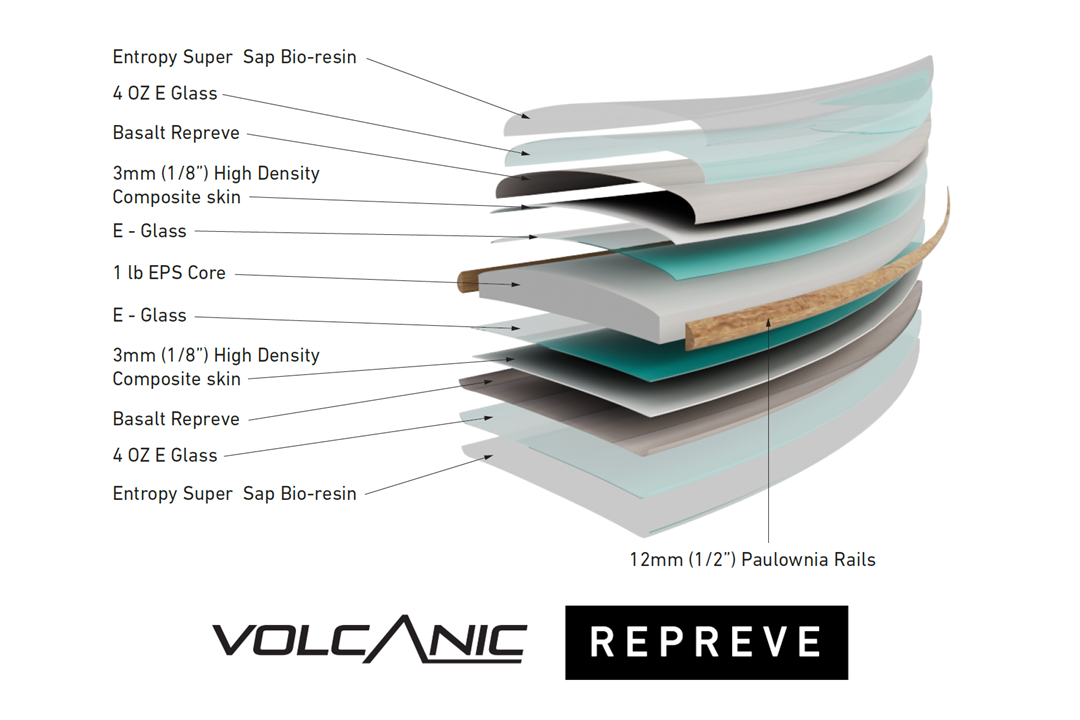

Volcanic Tech is made from Basalt Fibers Extruded from Volcanic Rocks that are crushed, melted and extruded into woven fibers that make up the cloth. The manufacture of basalt fiber requires the melting of the crushed and washed basalt rock at about 1,500 °C (2,730 °F). The molten rock is then extruded through small nozzles to produce continuous filaments of basalt fiber. Those filaments are then chopped into long stem fibers and woven into lamination cloth fiber. The cloth has similar characteristics to carbon as it relates to strength and weight however because the fibers are derived from Organic Raw materials, when combined with Bio Resins it serves as slightly better ECO alternative than using traditional glass fiber cloth.

Basalt fiber has been around for decades yet is a relative newcomer to fiber reinforced polymers (FRPs) and structural composites as it relates to surfboard construction. It has a similar chemical composition as glass fiber but has better strength characteristics, and unlike most glass fibers is highly resistant to alkaline, acidic and salt attack making it a good candidate for surfboard manufacturing.

Comments